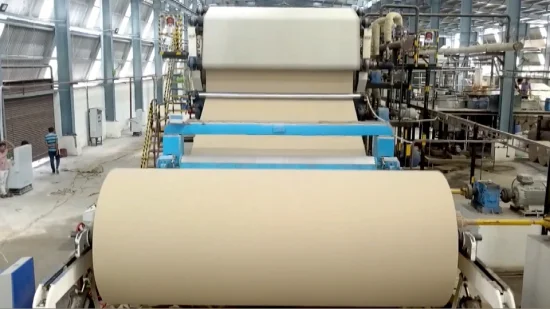

Big Roll Kraft Paper Making Machine Waste Paper Recycle Production Line

Overview Package size per unit product 3333.00cm * 3333.00cm * 3333.00cm Gross weight per unit product 333300.000kg Prod

Basic Info

| Model NO. | 1092/1575/1880/2100/3600 |

| Warranty | 1 Year |

| Type | Special Paper |

| Sheet Former Type | Cylinder Mould |

| Paper Thickness | Normal Specification Paper |

| Automation | Automatic |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | Video Meeting and Oversea Installation |

| Product Name | Kraft Fluting Corrugated Paper Making Machine |

| Raw Material | Waste Carton or Pulp |

| Paper Weight | 80~200GSM |

| Paper Roll Width | 2500mm~2600mm |

| Output Capacity | 12~15 Tons Per Day |

| Transport Package | Seaworthy |

| Specification | 48000*2980*5450mm |

| Trademark | YDF |

| Origin | Shandong Province China |

| HS Code | 8441809000 |

| Production Capacity | 50-200tpd |

Packaging & Delivery

Package size per unit product 3333.00cm * 3333.00cm * 3333.00cm Gross weight per unit product 333300.000kgProduct Description

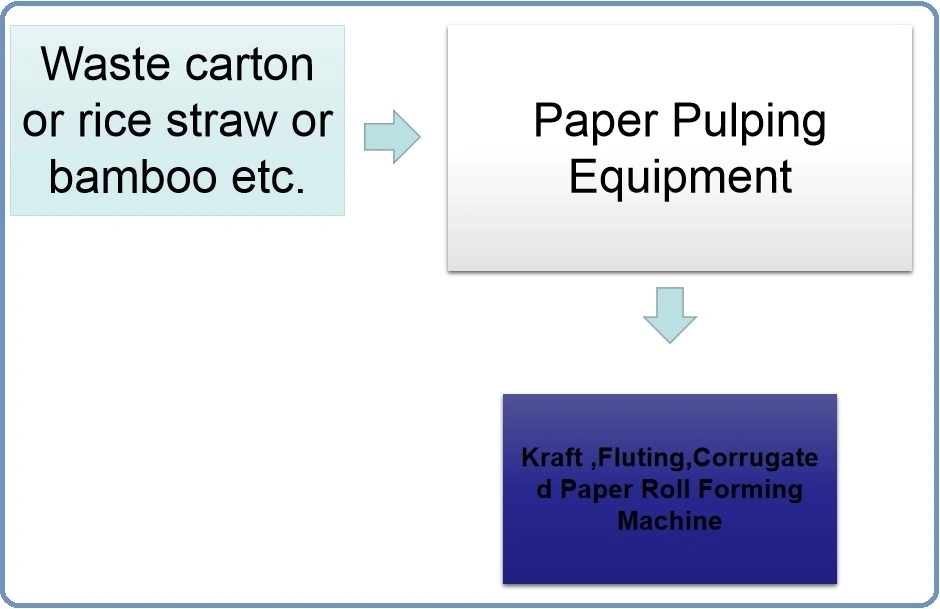

This machine can convert Waste carton ,wood ,rice straw etc into kraft corrugate paper roll.

| Pulping system is the waste carton, waste paper edge and other raw materials after breaking, grinding, screening and other procedures, made into the fiber water suspension to meet the requirements of paper making, and then through the flow system sent to the paper machine copy resulting in meeting the requirements of the user process. |

| Paper making machine is a paper machine which can make paper by dewatering, extrusion and drying the suspended pulp. The raw materials used are: waste cartons, wood pulp pull, etc. It can produce kraft paper, high strength corrugated paper, shopping bag paper, fruit paper and so on. Reliable quality, stable performance, easy operation, energy saving and environmental protection, is the ideal product in papermaking machinery. |

Product Parameters

| Paper machine technical description: | |

| Corrugated paper, etc. |

| 80 ~250gsm |

| Three garden net double cylinder |

| 12-15T/24h |

| 2500mm |

| 60m/min |

| 20-50m/min |

| 200m/min |

| G2.5 level |

| G4 level |

| G1.6 level |

| AC motor, digital display division frequency conversion speed regulation drive |

| Left and right mobile phones (selected by the user) |

| 3400mm |

| Dryer : Ø 2500mm × 2 th |

| Cage : Ø 1500 mm ×. 3 th |

Send to us