Double Layer Headbox for Dual Layer Web Pilot Paper Machine Sale Well

Basic Info

| Warranty | Lifetime Warranty |

| Type | Special Paper |

| Sheet Former Type | Fourdrinier Wire |

| Paper Thickness | Normal Specification Paper |

| Automation | Automatic |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | Lifetime Warranty |

| Paper Width at Pope Reel | 400 mm |

| Speed of Wire | 30-50 Meter / Min |

| Substance | 90-150 G/Square Meter |

| Capacity | 3tpd at 400mm, 120GSM,50m/Min, 22.5hrs/D |

| Raw Material | Selected Occ |

| Transport Package | Wooden Box with Steel Tube Frame in Container |

| Trademark | BANNOR |

| Origin | China |

| Production Capacity | 1000set/Year |

Product Description

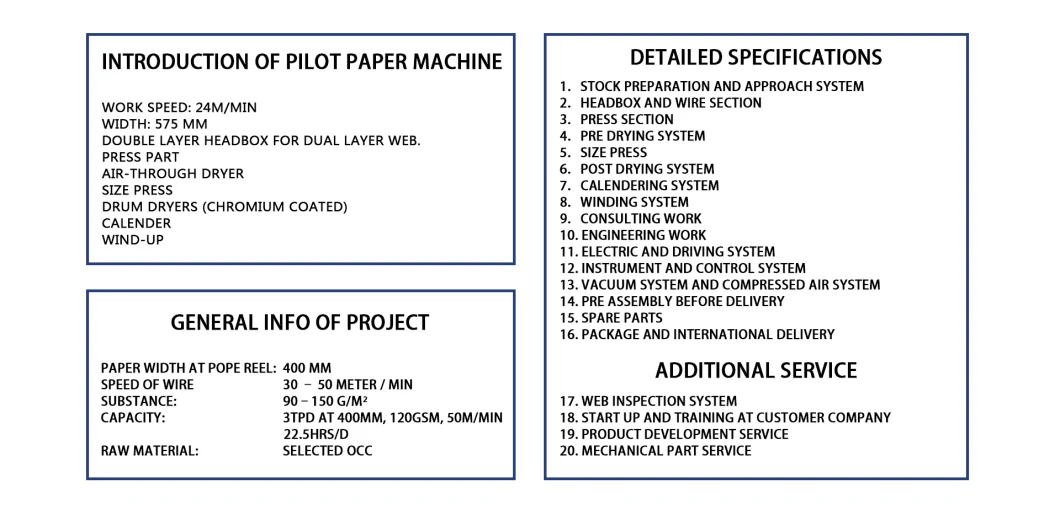

Introduction of Pilot Paper Machine

Work speed: 24m/min Width: 575 mm Double layer headbox for dual layer web. Press PartAir-through dryer Size press Drum dryers (chromium coated) CALENDERWind-up

General Info of Project

Paper width at pope reel: 400 mm Speed of wire: 30 - 50 meter / minSubstance: 90-150 g/m² Capacity: 3tpd at 400mm, 120gsm, 50m/min 22.5hrs/d Raw Material: Selected OCC

Detailed Specifications

1. Stock Preparation and Approach System 2. Headbox and Wire Section 3. Press Section 4. Pre Drying System 5. Size Press 6. Post Drying System7. Calendering System 8. Winding System 9. Consulting Work 10. Engineering Work 11. Electric and Driving System 12. Instrument and Control System 13. Vacuum System and Compressed Air System14. Pre Assembly Before Delivery 15. Spare Parts16. Package and International Delivery

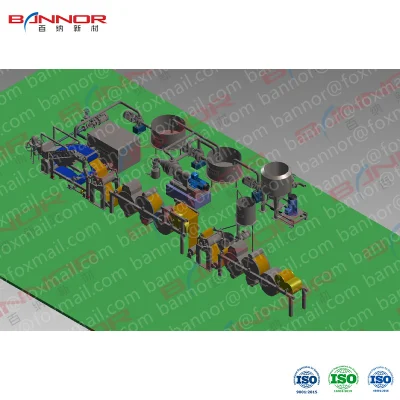

Appearance DesignAppearance design of Pilot Paper MachineAbout UsInternational ExhibitionsOur CertificateFactory StrengthFAQ

FAQ:

Q: Are you a manufacture?

A: Yes, we have been in providing professional products in this field for 30 years.ZIBO BANNOR NEW MATERIAL TECHNOLOGY is a high-tech enterprise with all vitality, potential and comprehensive strength. The company is located in the Zibo Science & AMP; Technology Zone, a unique place with beautiful scenery and gifts of nature

Q: Where do you sell your products?

A: Bannor has wide cooperation with Europe and America companies, we devoted ourselves to the promotion of paper machinery all over the world. Bannor always adheres to the modern business philosophy of "quality, credibility, innovation, and service", strive for survival with quality, seeks development with integrity, dedicates to serve our customers, and gradually expands the international market. The products sell well in Germany, Sweden, Austria, Bolivia, Vietnam, Bangladesh, India, Pakistan, Brazil, Argentina, and other countries

Q: How to install the machine?

A: we can help with the installation by vedio, email, picture. if it is a large project, we can arrange for our worker to help you to install it in your country

Q: How do you pack the products?

A: Normally as the export standard packaging or as your requirement

Q: What's your available port of shipment?

A: Qingdao port, Shanghai port, and so on

Q: Is it customized available?

A: Yes, according to the detailed drawing you provided.