Headbox Forming Carton Paper Making Machine

3200mm Liner Paper Production Line with 100T/D I.Technical parameter 1.Raw materials: waste carton,waste paper, pulp boa

Basic Info

| Model NO. | 3200mm |

| Customized | Customized |

| Condition | New |

| After-sales Service | Yes |

| Installation | Onsite Installation |

| Plant Design | Free |

| Test Run | Free |

| Training | Free |

| Raw Material | 100% Recycle Paper;Virgin Pulp |

| Transport Package | Standard Export Package |

| Specification | ISO |

| Trademark | DINGCHEN |

| Origin | Qinyang City, Henan Province |

| HS Code | 84392000 |

| Production Capacity | 30sets Per Year |

Product Description

3200mm Liner Paper Production Line with 100T/DI.Technical parameter

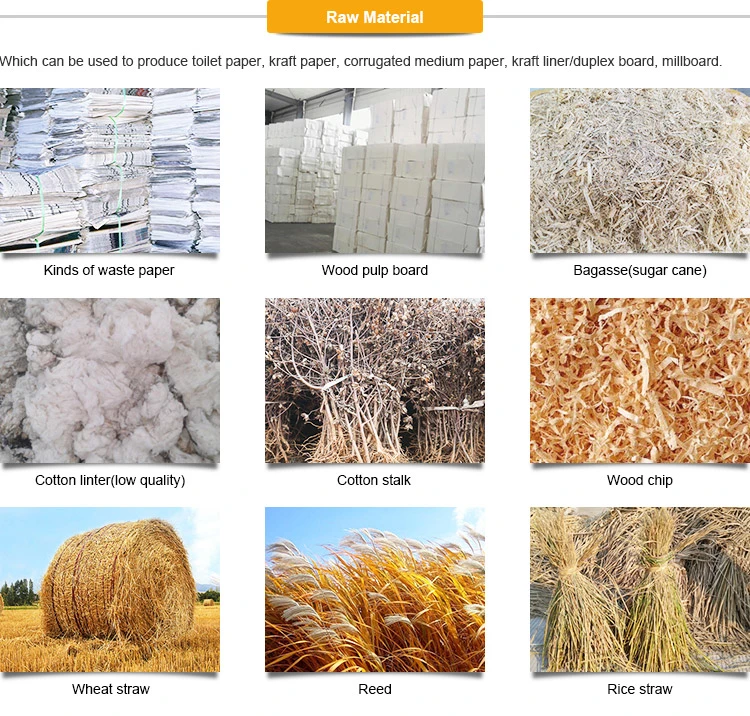

1.Raw materials: waste carton,waste paper, pulp board

2.Output paper: Fluting paper,kraft paper,test liner paper

3.paper width:3200mm

4.Wire width:3650mm

5.Output paper weight:80-220g/m2

6.Capacity: 100 T/D

7.Working speed:100-210m/min

8.Designing speed:250m/min

9.Rail gauge:4300mm

10.Drive way: Alternating current frequency converter speed control, sectional drive.

11.Paper driness :

out of cylinder mould:12%-16%

before into dryer: 42%-44%

end product:92%

II. The main structure with spec

- Wire part

| Brief introduction: (1) Head box A:Head box for machine speed 250m/min Material:Head box is welded by 304 stainless steel, In-wall is mirror polished,cotton swab to wipe not hang silk,pulp even roll is made by stainless steel, head box walking table is made by stainless steel B:step diffusion device Pulp inlet head pipe adopts step diffusion,small end has reflux mouth,capacity is about 10% of the pulp sprayed capacity of the lip.step diffusion is welded stainless steel, in-wall polished carefully.Finished in-wall which is close to pulp roughness is less than 0.4,cotton swab to wipe not hang silk C.Distributor Adopts three level distributor which made by organic glass which is connect with diffuser and body D.Pulp even roll 2sets ,made by stainless steel.roll body smoothness 0.4μm Inlet even roll opening 30%,lips even roll opening 50% In-wall and outside all polished,motor is 0.75kw ,4.3-43 r /min E.Upper lip adjustment device Include coarse control device and micro-control device ,micro control part is controlled by dial indicator which can adjust the cross gram distinction.micro-adjustment device distance us 110mm.Fastener is made by stainless steel F. Body is made by 304 stainless steel plate.upper lip and bottom lip is made by 316 stainless steel,surface polished,the side attached to the pulp is mirror polished. Stainless steel fastener G.Injection spray pipe to remove the foam of the pulp surface and avoid hanging the pulp in in-wall. Clean water for the sprayer has to be filtrated.Ø25stainless steel pipe equipped with private sprayer,stainless steel fastener H.Walking table is for adjusting the upper lips ,made by 304 stainless steel checkered steel plate , handrail made by 304 stainless steel pipe,stainless steel fastener

A.Dewatering element(seen in the pictures) B.breast roll: Roll body wall thickness 16mm,covered by 10mm rubber,shore hardness "A"98°±2°,shaft head 1:12taper,two sides have disassemble bearing hydraulic oil hole,grease lubrication C.driving roll:Roll body wall thickness 20mm,covered by 10mm rubber,shore hardness "A"98°±2°,shaft head 1:12taper,two sides have disassemble bearing hydraulic oil hole,grease lubrication. D.Vacuum couch roll:Stainless steel shell,bearing house is cast iron,vacuum box is welded by stainless steel ,shaft is cast steel,double vacuum room,Suction mouth width 135/90,Opening:φ8/φ13,Opening rate:25%-65% ,double helix. Air tyre sealing strip,pressure 0.06-0.1Mpa E. leading roll:Roll body wall thickness 16mm,covered by 10mm rubber,shore hardness "A"98°±2°,shaft head 1:12taper,two sides have disassemble bearing hydraulic oil hole,grease lubrication.

|

Company Information Zhengzhou Dingchen Machinery, located in Central China, is a professional machinery manufacturer focusing on the R&D and production of paper making machines.Our products include paper making machines,pulp making machine,parts and paper converting machines such as kraft paper machines,corrugated paper machines,tissue/toilet paper machines,office paper machines, newspaper machines and so on. Our factory gathers and trains many essential technicians and management system to ensure all products meet the quality of ISO and update constantly! Our products have been exported to many countries and regions, such as America, Egypt, India, Fiji, Iran, Ghana ,Paraguay, Russia, Syria,Pakistan, Tanzania, and Uzbekistan. Our products and services have won customers' consistent affirmations.have won customers' consistent affirmations.We have a large scale of products regarding paper machinery, including:A.Pulping equipment (D-type hydrapulper, cleaner, DD refiner, pressure screen, screen basket, pulp pump etc.)B.Paper machinery (Tissue/Toilet paper machine, Multi-fourdrinier paper machine, head box, cylinder mould, dryer cylinder, roller etc.) C.Paper making finished devices (Paper calender, pope reel,size press, paper rewinder etc.)Meet customers' requirements and exceed customers' expects.We wish to found long-termcooperation with your companyTechnical Advantage 1.Experienced producing team2.Advanced technological strengthProduct Advantage 1.Through the international authentication2.The same material the most preferential price3.A lot of varieties for the customer to chooseService Advantage 1.Technical consultation2.Project evaluation3.Detailed design of factory4.Installing and testing the whole production line5.Training engineers and workers6.Supplying spare parts for long timeThe business process1.send your requirements:raw material,capacity,paper grammage2.we make the solution to you3.come visit and negotiate4.sign contract5.first payment6.production7.pay spare money8.delivery9.installation ,training,test run10.production consultlation

Packaging & Shipping

Our Services

FAQ

11813 Rear Section Kit :next

Send to us