Paper Mill Machinery Guide Rolls Screen Guide Roller

Basic Info

| Model NO. | AT |

| Surface Treatment | Polishing |

| Manufacturing Process | Forging |

| Material | Stainless Steel |

| Diameter | 100-1600mm |

| Working Face | 1200-7500mm |

| Center Distance | 1300-8000mm |

| Rubber Thickness | 20mm-35mm |

| Shaft Head Material | 40#Steel |

| Roll Material | Cast Iron/Carbon Steel |

| Working Speed | 200m/Min-2500m/Min |

| Dynamic Balance | 250-1200m/Min G1.6 |

| Transport Package | as Model |

| Specification | as the model |

| Trademark | AT |

| Origin | Henan China |

| HS Code | 84391000 |

| Production Capacity | as The Model |

Product Description

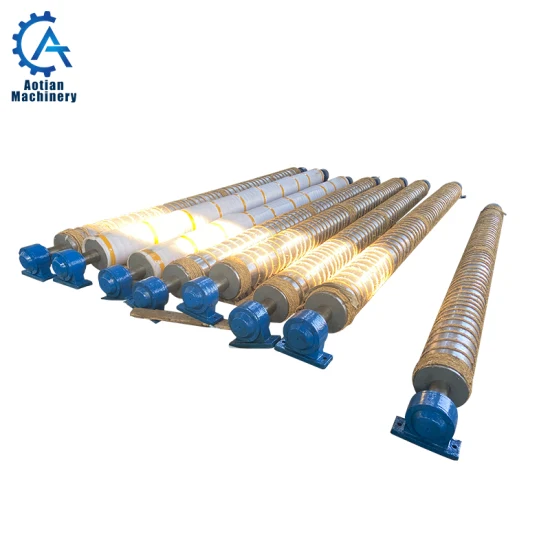

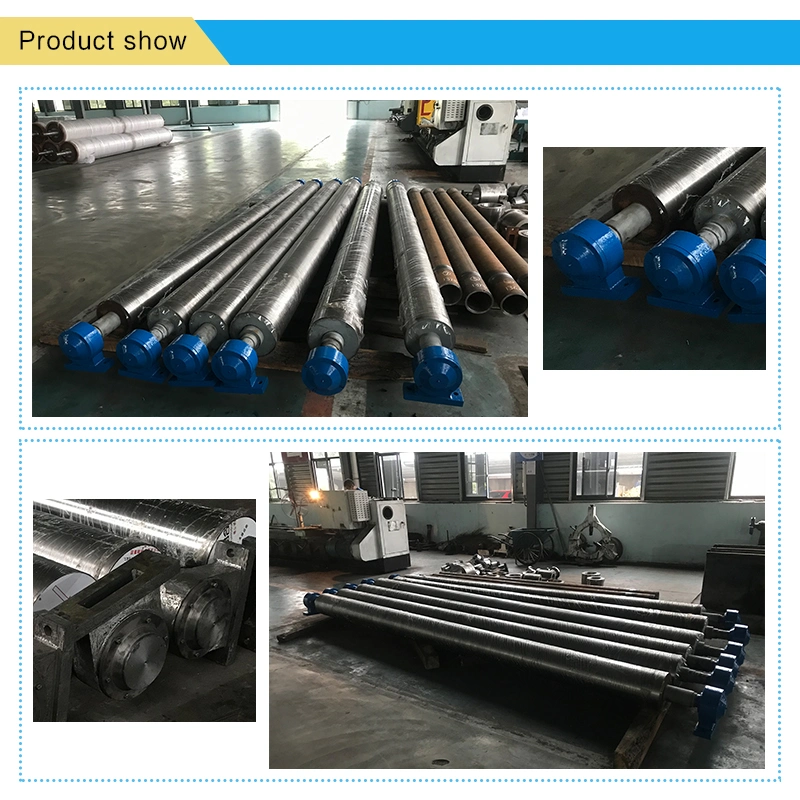

Paper Mill Machinery Guide Rolls Screen Guide RollerProduct DescriptionPaper machine guide rolls are divided into two types: felt rolls and screen guide rolls. The application parts include pressing, drying, crimping, rewinding and other parts. Guide rolls guide and drive the wire and felt in the wet end and drying section of the paper machine. The guide rollers in both areas use the same bearings. However, different lubrication and sealing are used depending on the application location. Due to different working conditions, the wet end and dry section need to be lubricated with their own oil circulation.Structural Principles

The guide roller is composed of a roller core, a bracket, a baffle plate, an idler roller and a bearing connection. The surface of the idler roller is a concave arc surface, which can automatically center the steel pipe on the idler roller. The setting of the baffle plate can limit and fix the steel pipe. Prevent the steel pipe from detaching from the roller, the roller core can roll with the frame during use, the roller rotates with the roller core through the bearing, reducing rolling friction, small rolling resistance, prolonging the service life of the guide roller, and facilitating the post-processing of the steel pipe , to improve the processing efficiency of steel pipes.

Product Parameters| Diameter | 100-1600mm |

| Working face | 1200-7500mm |

| Center distance | 1300-8000mm |

| Rubber thickness | 20mm-35mm |

| Shaft head material | 40#Steel |

| Roll material | cast iron/carbon steel |

| Working speed | 200m/min-2500m/min |

| Dynamic balance | 250-1200m/min G1.6 |

AOTIAN have sanitary paper machine, culture paper machine, kraft paper machine, corrugated paper machine, etc machinery.There are our best selling products,the quality is praised by customers all over the world.

Company ProfileAotian Machinery Manufacturing was founded in 1985, it has a leading position in paper machinery of China.We have a professional production, research and development, sales team. Our main products are paper machine,pulping equipment and paper machine parts.And we have the product certificate,we will meet and exceed your expectations. Please contact our custom service for details .

The company has passed ISO9001:2000 international quality management system certification, self-supporting and export rights.All products comply with GB and ISO standards.The enterpries passed the ISO9001 international quality system certification in 2000.

Our products have received good comments from customers all over the world.

We have many customers in Egypt, Middle East, Argentina, Uzbekistan, Turkmenistan, Malaysia, Vietnam, Pakistan , Russia,etc. And we are looking forward to establish cooperation relationship with friends all around the world.We warmly welcome you on-the-spot investigation!

Packaging & ShippingPackagingProducts will packaged according to their shapes, weight, transport distance and transport modes.Large machines will be packaged in sections.every part export machinery will be in standard export package seaworthy wooden case waterproof film, straw rope, carton box etc.ShippingSea transportation is from Qingdao seaports or other china main ports.The delivery time is decided by machine types.But we also try to make it follows your needs.

Our service

Pre-sales service:1.Offering comprehensive technical and business consultation services.2.Proposing the most suitable scheme and equipment for our clients.3.Designing and fabricating targeted products according to the special requirements of clients.4.Training periodically high qualified service technician.After-sales service:1.Assisting our clients for foundation construction of equipment.2.Dispatching engineers to install and debug equipment.3.Regularly visit clients to solve production problems.FAQ

Q1. Are you factory or trade company?A1. We are manufacturer, we also supply trade service.Q2. What about your price?A2. We always supply the products with low price, because we believe this is the way to build long-term business and earn good reputation.Our price is 3%-5% lower than the average market price.Q3. How about your delivery time?A3: Generally, it will take 15-20 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.Q4: How do you make our business long-term and good relationship?A4: 1. We keep good quality and competitive price to ensure our customers benefit;

Contact us

We believe:your first order profit is key based on excellent quality and competitive price . All above information proved our quality is perfect. Send us inquiry, you will find that we are your most satisfied choise.Look forward to hearing from you sooner and establishing a long friendly business relationship with you.We promise we will do our best to help you .As most paper machinery products, pulping equipments, roll products need to be customized, the prices and sample prices shown on our product details page are for reference only, please contact our professional customer service and tell us your specifications and sizes, you will get a more reasonable and exciting price!