Paper Mill Pope Reel Paper Roll Winding Silk Reeling Machine

Paper mill pope reel paper roll winding silk reeling machine Product description This machine is used for the first set

Basic Info

| Model NO. | AT |

| Warranty | 1 Year |

| Type | Cultural Paper |

| Sheet Former Type | Fourdrinier Wire |

| Paper Thickness | Thin Paper |

| Automation | Automatic |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Year |

| Net Paper Width | 1760-5200m |

| Design Speed | 500m/Min |

| Working Speed | 100-450m/Min |

| Paper Grade | Cultural Paper, Wrapping Paper |

| Paper Grammer | 100-360 GSM |

| Transmission Mode | Unified Arrangement with Paper Machine Drive |

| Control Mode | Electronic Control, Air Control, Rope and Paper Fe |

| Reel Paper Diameter | 1800-2500mm |

| Transport Package | as Model |

| Specification | As model |

| Trademark | Aotian |

| Origin | Henan |

| HS Code | 84391000 |

| Production Capacity | 5sets/Month |

Product Description

Paper mill pope reel paper roll winding silk reeling machineProduct description

This machine is used for the first set of finishing equipment behind the paper machine. The roll cylinder is operated actively, and the roll is driven by friction to complete the paper winding. By adjusting the pressure of the auxiliary arm and the cylinder of the main arm to adjust the linear pressure between the roll and the cylinder, the operation can meet the needs of different kinds of paper and make the paper rolled down from the paper machine into a compact and uniform roll paper.chine spare parts machinery recycling pulp bleacher

Net paper width | 1760-5200m |

Design speed | 500m/min |

Working speed | 100-450m/min |

Paper grade | Cultural paper, wrapping paper |

Paper grammer | 100-360 GSM |

Transmission mode | Unified arrangement with paper machine drive |

Control mode | Electronic control, air control, rope and paper feeding |

Reel Paper diameter | φ1800-2500mm |

These are all our hottest products.

Both the quality and the price are highly appraised by customersCompany information

Qinyang Aotian Machinery Manufacturing was founded in 1985, according to the modern enterprise mechanism into a large-scale standardized joint-stock enterprises, with 278 workers,including 23 engineers and technicians,15 senior engineers.In general, Aotian is in the leading place of paper-making industry in China

Our factory covers an area of about 60000 square meters, has a technical research and development department, eight large modern processing workshops, and a quality inspection center, with more than 50 large and medium-sized equipment and scientific research design, manufacturing, testing, assembly and debugging and a series of functions.

The company has passed ISO9001:2000 international quality management system certification, self-supporting and export rights.

Papermaking machine and papermaking machine parts is our company's main product.Our factory can produce mechanical pulping equipment, chemical pulping equipment, paper scrap deinking equipment, pulping and paper-making sewage treatment equipment, paper-plastic of composite paper separating equipment, etc.We will provide whole services according to our clients' demand, like technical design, equipment production, installation and test instruction and so on. We will meet and exceed your expectations. Please contact our custom service for details.

Certificate

The company has passed ISO9001:2000 international quality management system certification, self-supporting and export rights.Exhibition

We go to world famous exhibitions every year.

Constantly promote and publicize the company's brand, to the majority of customers to show the strength and image of the company.The high concentration of visitor flow, information flow and capital flow in the exhibition can help our company learn from each other and improve its competitiveness.

Our Service

Pre-sales service:

1.Offering comprehensive technical and business consultation services.

2.Proposing the most suitable scheme and equipment for our clients.

3.Designing and fabricating targeted products according to the special requirements of clients.

4.Training periodically high qualified service technician.

After-sales service:

1.Assisting our clients for foundation construction of equipment.

2.Dispatching engineers to install and debug equipment.

3.Regularly visit clients to solve production problems.

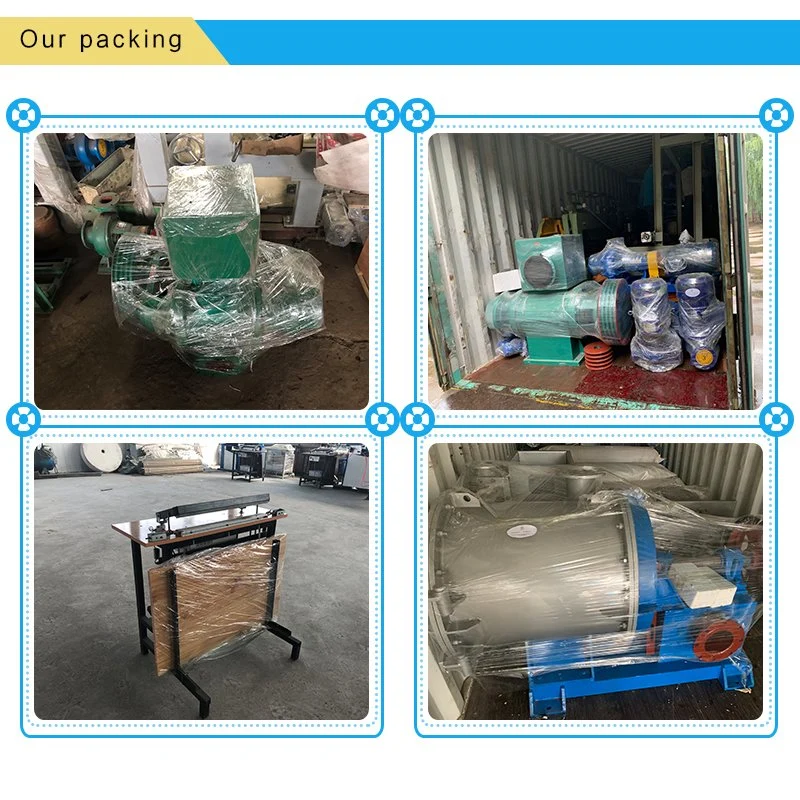

Packaging&shipping

PackagingProducts will packaged according to their shapes, weight, transport distance and transport modes.Large machines will be packaged in sections.every part export machinery will be in standard exportpackage seaworthy wooden case waterproof film, straw rope, carton box etc.ShippingSea transportation is from Qingdao seaports or other china main ports.The delivery time is decided by machine types.But we also try to make it follows your needs.

Q: Why don't person reply to me?

A: Our person is 24 hours online. When nobody reply you , please leave your requirements on email or chat tool,we will reply you as soon as possibleQ: What can I get suitable scheme basis on my requirement ?

A: Please tell me what raw material you want use and how many capacity you want produce per day when you sent email to me .We will be provide better offer for you .Q: Will you send engineers to design our plant and install the equipment?

A: Yes, Our factory will arrange engineer to supply the professional drawing and install and train the workers about adjusting the equipemnt ,disposing of the trouble maybe happen and maintenance of the machine , after training ,the workers will get work license we distribute .Q: What is your terms of payment ?

A: One Year.We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service .You will be welcome to contact us with any problem might occurred .Send to us