Machine Paper Straws Pipes Paper Product Making Machinery Product Packing Machine

Basic Info

| Model NO. | 550 |

| Application | Drinks, Beverage, Machinery & Hardware, Milk & Soft Drinks |

| Type | Double Sealing Machine |

| Forming Species | Melt Molding |

| Forming Function | Seal |

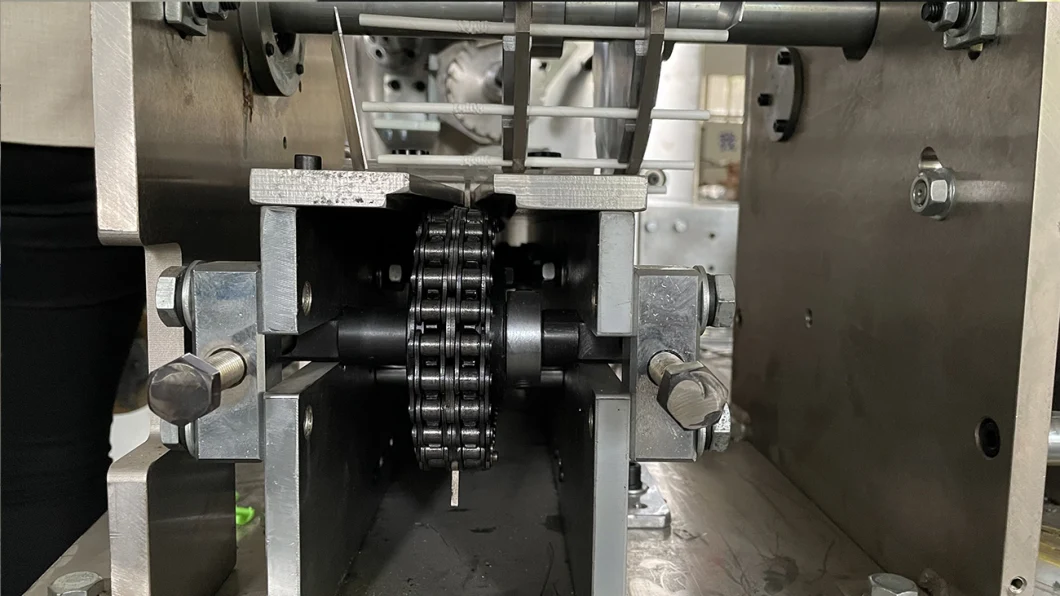

| Driven Type | Mechanical |

| Material Type | Paper Film |

| Packaging | Paper Film |

| Packaging Material | Paper |

| Machine | U Shape Drinking Straw Packing Machine |

| Speed Output | 500- 700PCS/Min |

| Control | by Frequency Converter |

| in-Diameter | 3.8mm and 4.8, mm |

| Packing Shape | 22mm(Pitch)Times, 100~140mm(Wide) |

| Wrapping Straw | 5mm-20mm |

| Motor Power | 2.2kw |

| Machine Weight | 1000kg |

| Packing Material | BOPP or Coated Paper |

| Count Function | Have |

| Marketing Type | Hot Product 2023 |

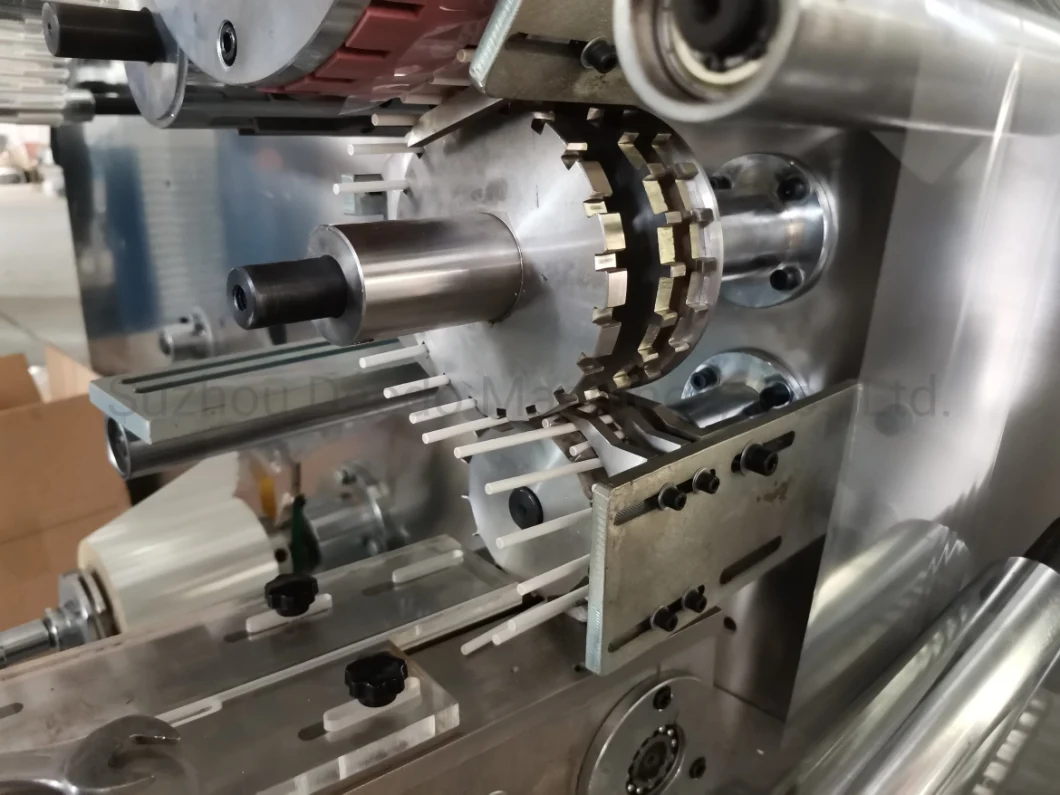

| Core Components | Bearing, Gearbox, Motor, Gear |

| Driven | Electric |

| After-Sales Service P | Online Support |

| Diamaeter | Staandard Diameter |

| Transport Package | Wood Packing Machine |

| Specification | 2200mmx1800mmx1700mm |

| Trademark | SHINE STRAW |

| Origin | Jiangsu, China |

| HS Code | 8422303090 |

| Production Capacity | 200 Sets Per Year |

Packaging & Delivery

Package size per unit product 2600.00cm * 1300.00cm * 1700.00cm Gross weight per unit product 2600.000kgProduct Description

High speed U Shape Straw Paper For Juice And Milk Packing Wrapping machine

SS-033 U-shape straws auto packing machinesProduct Description

DESCRIPTION

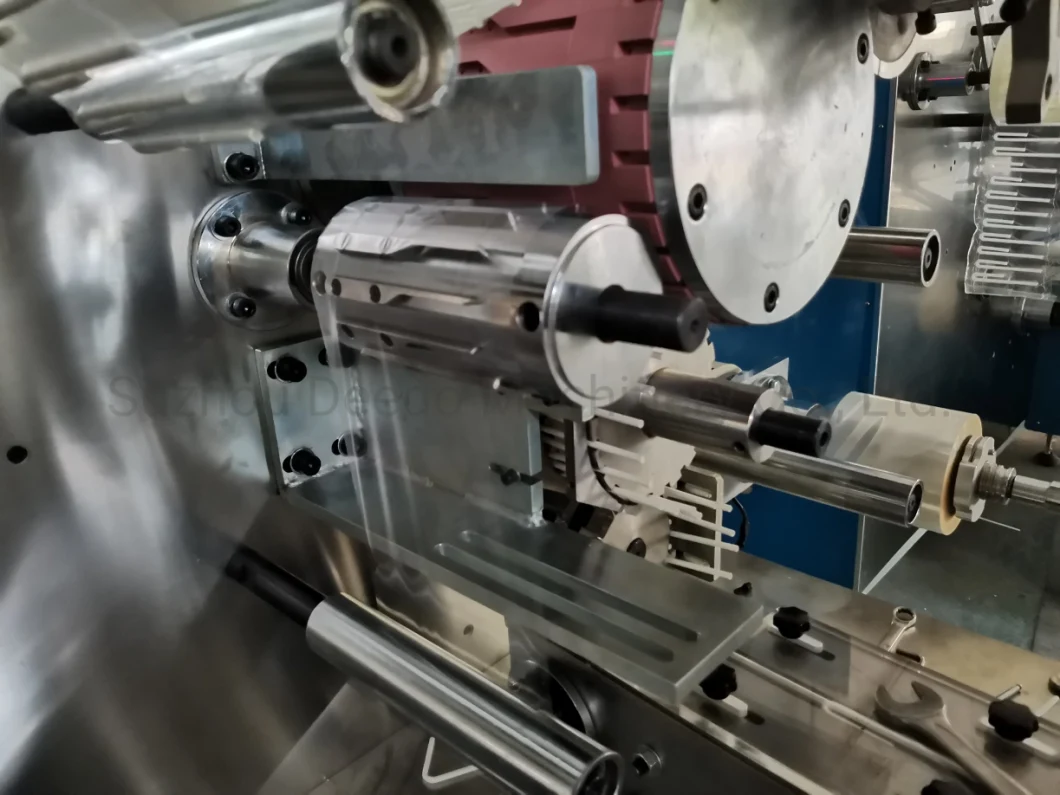

This JX033 machine can bend flexible drink straws into U-shape and automatically pack them into bags.The complete machine is composed of a driving motor, thin film rolling device(2 groups), a driven system, an unloading device, a straw filling device, a sealing device, a restoring substandard products device and others.The machine boasts easy operation and reliable quality. It is mainly used as the auxiliary equipment for sterile packed drinks such as BOX packing.CHARACTERISTICSPacking of single straws and the completion of bending, filling and packing of straws at a timeAutomatic counting and batch alarmAdjustable packing speed Product ParametersSPECIFICATIONS:

| Driving Motor | 2.2kw(control by frequency converter) | |

| Production Capacity | 500~700pcs/min | |

| Packing method | four sides sealing | |

| Specifications of the packing film | Material | can be hot sealed such as Bopp |

| Shape | Roll | |

| Roll diamtere | Max:280mm | |

| Internal diameter of paper tubes | 76mm | |

| Width of film | Max:180mm | |

| Thickness of film | 20μ-30μ | |

| Packing shape | 22mm(pitch)× 100~140mm(wide) | |

| Straws specifications | In-diameter | Ø 3.8mm Ø 4.8mm |

| Thickness | 0.19~0.25mm | |

| Length of U-shape model | 90mm(smaill type)\105mm(middle type),128mm(big type) | |

| Other specifications are Customizable | ||

| Machine size(L×W×H) | 2200 × 1800×1700mm | |

| Machine weight | 1000kg | |

CertificationsCompany ProfilePackaging & ShippingOur Advantages

1.Quality Control:

· We have technical, engineer team design the sample machinery before enter into market

· Production QC team ensure the machine manufacturing quality

· We will running every machine after finished before shipment

· Optional choose by client running the machinery by material

2.Service System:

· Pre-sale: We given client the details technician offer, sign the sales contract etc.

· In-sales: We supply the details layout, installation instruction, technician support for the clients;

· After sales: We arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer